January 26, 2026

Why MP Materials Matters

MP Materials (NYSE: MP) is often described as America’s rare earth champion – it owns the only large-scale rare earth mining and processing site in the United States[1]. Rare earth elements (REEs) are a group of 17 metals crucial for modern technologies, from electric vehicle motors to wind turbines to defense systems. MP Materials operates the Mountain Pass mine in California, which was responsible for about 15% of the rare earth content used globally in 2020[1]. This makes MP a strategically important player at a time when the U.S. and its allies are seeking to secure supply chains for these critical minerals outside of China. In fact, China dominates rare earth production – mining ~69-70% of world supply and refining over 90% of rare earths as of 2024[2][3]. MP Materials’ mission is to rebuild a fully domestic rare earth supply chain, reducing reliance on imports. This strategic importance has not gone unnoticed: the U.S. government has effectively chosen MP as a national rare earth champion, recently backing the company with a major Department of Defense partnership to ensure the U.S. has its own source of rare earth magnets[4]. In short, MP Materials matters because it sits at the nexus of technology, resources, and geopolitics, aiming to provide the raw materials that power the modern economy – from iPhones to F-35 jets – without needing to depend on foreign adversaries.

What MP Materials Actually Does

MP Materials’ core business is mining and processing rare earth elements, with a focus on those used in high-strength permanent magnets. At its Mountain Pass facility (the largest rare earth mine in the Western Hemisphere), MP extracts ore and refines it into rare earth oxides[5]. Historically, the company’s revenue came from selling concentrated rare earth material (rich in neodymium and praseodymium (NdPr), the key magnet metals) to overseas processors (primarily in China). However, MP is now aggressively moving downstream to capture more value. It has built separation facilities to produce purified NdPr oxide on-site instead of just shipping concentrate. Even more importantly, MP has launched a magnet manufacturing division (MP Magnetics). In Fort Worth, Texas, the company is commissioning a factory to produce neodymium-iron-boron (NdFeB) magnet alloy and finished magnets, using Mountain Pass as the source of raw material[6][7]. In other words, MP Materials is transforming from a miner into a fully integrated producer that can mine rare earths, refine them into oxides, reduce them to metal, and then make the finished magnets needed for electric motors and generators[7].

How does MP make money? Currently it has two segments: Materials (selling rare earth oxides or concentrate) and Magnetics (selling alloy and magnet products). The Materials segment has been the legacy revenue driver – for example, in 2022 MP sold over 43,000 metric tons of rare earth oxide in concentrate form[8], generating record revenue of $527 million[9]. But as of 2025, the company has begun to shift its sales toward higher-value products. By Q3 2025, MP’s new Magnetics segment had already grown to $21.9 million in quarterly revenue (from near zero a year prior) as it ramped up production of magnet precursors[10]. Meanwhile, the Materials segment revenue declined as MP deliberately ceased selling raw concentrate to China in order to process it in-house[11][12]. Going forward, MP’s business model will center on selling separated NdPr oxide and NdFeB magnet alloy/magnets to end-users like electric vehicle makers and defense contractors, rather than being just a supplier of unrefined ore.

Notably, MP Materials already has long-term supply agreements that anchor its business. In late 2021, it signed a binding contract with General Motors (GM) to supply U.S.-sourced rare earth alloy and magnets for more than a dozen of GM’s electric vehicle models using the Ultium platform[13][14]. The Fort Worth magnet factory is designed to produce about 1,000 tonnes of finished magnets per year – enough to power ~500,000 EV motors – to fulfill orders like GM’s[15][16]. MP has also secured a ~$500 million deal with Apple, which involves supplying rare earth materials (and likely magnets or recycled content) for Apple’s supply chain[17]. These partnerships, alongside support from the U.S. government, mean that MP already has built-in customers for its future production. In sum, MP Materials’ business spans the rare earth supply chain end-to-end, from digging ore out of the ground in California to refining and manufacturing the critical magnet components that companies like GM need for EVs[18][19]. This vertical integration is key to its value proposition.

The Big Picture: Rare Earths & Geopolitics

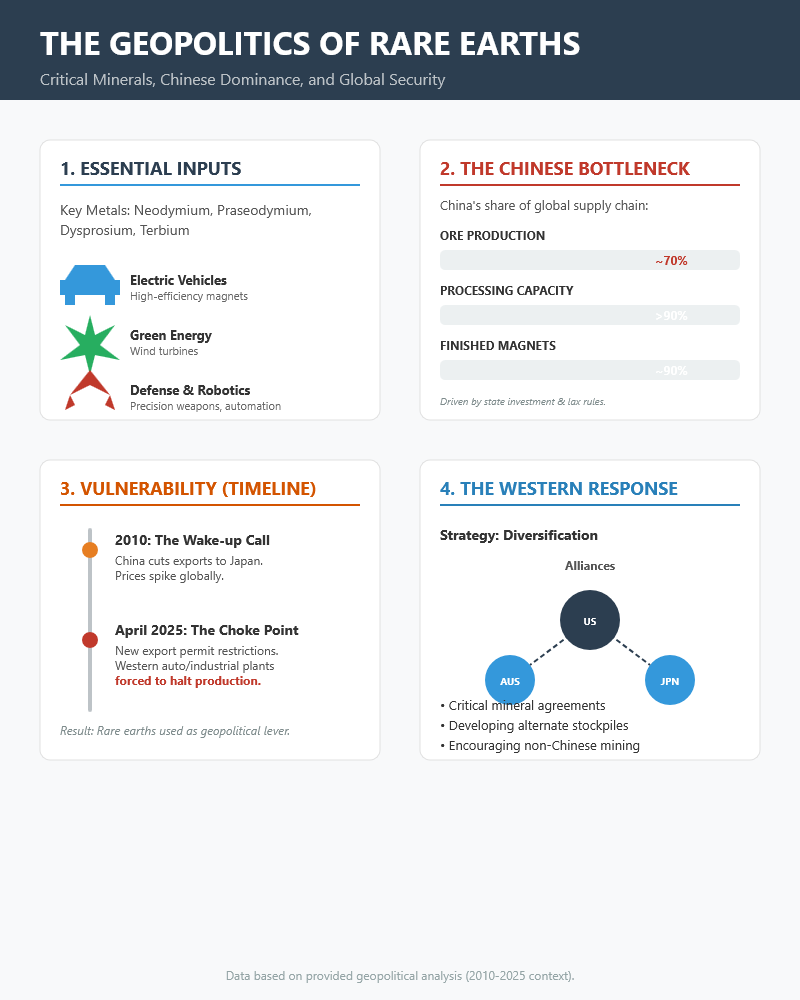

Rare earth elements may not be household names, but they have outsized importance in the global geopolitical and economic landscape. These metals (like neodymium, praseodymium, dysprosium, and terbium) are essential inputs for high-tech and green industries – they’re in the powerful magnets that make electric vehicles run efficiently, enable wind turbines to generate power, allow robotics and factory automation to function, and guide precision in defense weapons and aircraft[20][21]. The “big picture” issue is that China dominates every step of the rare earth supply chain, which creates a strategic vulnerability for the rest of the world. China accounts for roughly 70% of global rare earth ore production and over 90% of processing capacity[2][3]. It also produces around 90% of the world’s finished rare earth magnets[22]. This dominance isn’t due to geology – it’s largely the result of decades of state investment, lax environmental rules, and strategic policy by China that undercut competitors[23][24].

Western countries have learned the hard way that relying on a single foreign source for critical materials is risky. In 2010, China famously cut off rare earth exports to Japan during a diplomatic spat, causing prices to spike. More recently, in April 2025, Beijing imposed export permit restrictions on certain rare earth magnet materials, which “choked off” exports and even forced some Western auto and industrial plants to halt production due to lack of components[25]. These incidents served as a wake-up call: they illustrate how rare earths can be used as a geopolitical lever. Supply chain security for rare earths has therefore become a priority for the U.S. and its allies. Governments are now scrambling to develop alternate sources and stockpiles. The U.S., for example, has signed critical mineral agreements with partners like Australia, Japan, and others to encourage non-Chinese mining and refining[26].

China and the West are poised to compete for scarce heavy rare earth supplies. Global demand for rare-earth magnets is surging, and key heavy rare earth elements like dysprosium and terbium (needed for high-temperature magnets) are projected to slip into deficit. China’s near-monopoly in these materials poses a strategic challenge[27][28].

In this geopolitical context, MP Materials plays a pivotal role. It operates the only rare earth mine in the U.S., and adding domestic refining and magnet production gives the U.S. a measure of independence in this critical supply chain[29][22]. The company frequently highlights its mission of restoring “full rare earth supply chain in America”[30]. U.S. policymakers also view MP as a strategic asset – in July 2025 the Department of Defense (DoD) struck a multibillion-dollar partnership with MP to ensure the build-out of an end-to-end American rare earth magnet supply chain[31][32]. This deal is unprecedented (DoD will even become MP’s largest shareholder) and underscores how critical rare earths are deemed for national security[33][22].

In summary, the rare earths big picture is one of booming demand and concentrated supply. Global consumption of NdFeB magnets is expected to double by 2030 and even triple by 2035, driven by the EV revolution and renewable energy growth[34][21]. Yet China’s dominance and willingness to wield pricing or export controls create a precarious situation for Western industries. That’s why there is intense geopolitical focus on companies like MP Materials – they are on the front lines of an effort to diversify supply chains, mitigate China’s leverage, and secure the raw materials of the future. For investors, this means MP’s story cannot be separated from policy and geopolitics: government decisions, trade policies, and international relations will directly influence the company’s prospects.

Growth Opportunities

MP Materials sits in the middle of several powerful growth trends that underpin the bull case for its long-term prospects. Here are the major opportunities and tailwinds for MP:

- Electric Vehicles (EVs): The rise of EVs is perhaps the single biggest demand driver for rare earth magnets. Each EV motor typically uses 1–3 kilograms of NdFeB magnet material (mostly NdPr alloy, plus a bit of Dy for heat resistance)[35]. As automakers scale up EV production into the tens of millions of units per year, the need for NdPr will soar. In fact, industry analysts expect global NdFeB magnet demand to roughly double by 2030 thanks largely to EV growth[34][36]. MP’s move into magnet production positions it to directly supply this booming sector. Its supply agreement with GM is a prime example – MP will provide magnets for 500,000 EV motors per year at full ramp[15][16]. Beyond GM, as other auto OEMs look to secure non-Chinese magnet supply, MP could see more partnerships (the Apple deal indicates even tech companies are interested in rare earth supply). The electrification megatrend is a huge long-term opportunity.

- Wind Turbines & Renewable Energy: Modern wind turbines – especially large offshore units – use massive quantities of rare earth magnets in their generators. A single large direct-drive wind turbine can require hundreds of kilograms of NdPr magnets[37]. With global wind power installations growing steadily to meet clean energy goals, demand for magnet materials in this sector is set to climb. Permanent-magnet wind generators are favored for their efficiency and low maintenance, which means more NdFeB magnets per megawatt of wind capacity. MP Materials, by expanding NdPr production and magnet making, stands to benefit from the push for green energy infrastructure. Additionally, rare earths (like dysprosium) are used in high-performance generators and grid technologies, so the broader renewables and electrification trend supports MP’s market.

- Robotics & Automation: Industrial robots, drones, and advanced automation systems use electric motors and actuators that often rely on rare earth magnets for high torque-to-weight ratios. As AI-driven automation spreads in factories and logistics, the demand for precision motors (and thus magnets) will grow. MP’s magnets could find applications in everything from warehouse robots to autonomous drones. While this is a smaller segment than EVs or wind, it’s still a growth area where high-performance magnets are essential for efficiency and power density[20].

- Defense and Aerospace: Rare earths have long been important in defense – they’re in fighter jet sensors, missile guidance systems, satellites, and other military hardware[38]. NdFeB magnets and samarium-cobalt magnets are critical for many defense applications that require powerful, compact actuators and motors. The U.S. Department of Defense is literally investing in MP (via the July 2025 partnership) to ensure a domestic source for these needs[39][40]. This government support (including funding and guaranteed purchases) not only validates the demand in defense, but also provides MP with a secure revenue stream in this sector. As defense spending on advanced tech remains robust, MP can tap into steady, high-value demand for rare earth materials for military use.

- Magnet Manufacturing Value-Add: Moving into magnet production (Stages II and III of MP’s plan) is itself a growth opportunity because it captures more margin and opens new markets. Instead of just selling oxide at commodity prices, MP can sell finished magnets or alloys, which command higher prices and could be sold under long-term contracts. This vertical integration could allow MP to become a key supplier to OEMs in automotive, electronics, and industrial fields that prefer to buy finished magnet components rather than raw materials. There is also an opportunity for MP to supply other magnet manufacturers with intermediate products (for example, MP has mentioned supplying alloy flake to develop a diverse U.S. magnet supply chain[16]). Essentially, MP can grow by climbing up the value chain, increasing its TAM (total addressable market) from just raw rare earth oxide sales to the entire magnet market, which is worth billions.

- Government Incentives and Policy Support: MP is benefitting from a favorable policy environment. Western governments have introduced grants, tax credits, and procurement policies to encourage domestic rare earth production. In the U.S., the 2022 Inflation Reduction Act included advanced manufacturing credits (MP received a $58.5 million tax credit for its magnet factory under the Section 48C program[41][21]). The Department of Energy and Department of Defense have given out funding awards to accelerate rare earth processing capabilities – MP received prior DoD awards to support heavy rare earth separation. Looking ahead, proposed U.S. legislation could require defense suppliers to source U.S. rare earths, or EV subsidies might favor domestically-sourced materials. All these pro-industrial policies create a supportive backdrop for MP. The company’s designation as a strategic asset suggests it will continue to get tailwinds from grants, contracts, and possibly loan guarantees. Indeed, the recent DoD deal provides price floors and offtake guarantees for 10 years, which is an incredible form of support[42][43]. MP’s growth is tightly interwoven with government initiatives aimed at supply chain resilience.

In summary, MP Materials is leveraging strong secular trends – the electrification of transportation, the expansion of renewable energy, increasing automation, and heightened national security concerns – all of which drive higher demand for rare earth magnets. If MP executes well, it could ride these tailwinds for years, scaling its production to meet a market that is expected to triple by 2035 for NdFeB magnets alone[21]. Few other companies outside China are as well positioned across so many high-growth sectors that depend on rare earths.

The Bull Case

Why are investors excited about MP Materials? The bull case rests on the company’s unique strategic position, growth potential, and recent developments that de-risk its future. Here are the key points for the optimistic view:

- Strategic “Chosen One” with Government Backing: MP Materials has effectively been anointed as the U.S.’s rare earth supply chain champion. The July 2025 DoD partnership is a game-changer – the Pentagon will invest in MP (becoming a large shareholder) and has agreed to guarantee a price floor of $110 per kg for MP’s NdPr production for 10 years[42]. This means even if China tries to crash rare earth prices, MP’s core product has a protected price well above recent market levels (the floor is nearly double the ~$60/kg Chinese price that prevailed in 2023-24)[44]. Additionally, DoD committed to purchase 100% of the output from MP’s next magnet factory for a decade[43]. This kind of long-term offtake assurance and price stability is virtually unheard of in the mining world and gives MP a stable economic platform to build on[4]. In short, the U.S. government’s support significantly reduces MP’s downside risk and validates its importance. MP is not just another mining stock – it’s viewed as a strategic asset, and that backing can attract more investors and partners (Morgan Stanley has noted the U.S. “has effectively chosen MP” as the solution for critical minerals[4]).

- Huge Demand Tailwinds (EVs & Clean Tech Boom): The long-term demand outlook for MP’s products is very strong. Rare earth magnet demand is set to explode with the growth of electric vehicles, wind power, and advanced electronics. We’re talking about multi-decade secular growth in these industries. For instance, global neodymium-iron-boron magnet consumption is expected to double by 2030 and nearly triple by 2035[34][21]. MP’s planned production volumes (e.g. 10,000 tonnes of magnets per year by 2028 with its expanded facilities[45]) would capture a healthy share of this rising market. Investors bullish on EVs and renewable energy see MP as a pick-and-shovel play on those trends – as EV sales climb, so will demand for MP’s neodymium and magnets. The magnet factory in Texas (and the second “Stage IV” 10X factory announced for 2028) mean MP can sell a value-added product into a rapidly growing market. In essence, MP offers exposure to the green tech revolution (EVs, wind, robotics, etc.) without picking a specific car or turbine maker. This broad exposure to high-growth sectors excites growth-oriented investors.

- Vertically Integrated = Higher Margins and Resilience: By moving downstream into separation and magnets, MP is transforming its business model from a low-margin commodity supplier to a higher-margin specialty manufacturer. Magnet producers historically capture more profit per kilogram than miners do. If MP can successfully ramp its magnet production, it could enjoy better pricing power and more stable contracts (magnets can be sold on long-term agreements, whereas raw oxide prices can fluctuate). Vertical integration also makes MP more resilient to external shocks: for example, if China tries to undercut oxide prices, MP can still derive value by producing finished magnets (where Western buyers may pay a premium for non-Chinese finished goods). The end-to-end control from mine to magnet also means MP can optimize costs internally and potentially develop recycling loops (MP plans to recycle end-of-life magnets back into its process, further reducing reliance on fresh mining)[46][47]. Investors bullish on MP believe this strategy will lead to sustainable competitive advantages, as very few companies outside China can offer a one-stop domestic supply of rare earth magnets. Basically, MP is creating a moat in the form of a complete supply chain.

- First-Mover and Scale Advantage in the West: MP Materials is the largest producer in the Western Hemisphere and has a several-year head start in scaling production[1]. Its Mountain Pass mine produced over 42,000 metric tons of REO in 2022 – the highest ever in the U.S.[9][8]. The company has a “running start” compared to any potential U.S. competitors, given that Mountain Pass is already operational and expanding. Australian rival Lynas is significant in oxides, but Lynas does not make magnets and faces its own constraints (regulatory and capacity). In magnets, a few niche players (in Japan, Germany) exist, but MP is set to leapfrog them in volume with its planned 10,000 ton/year capacity[45]. If MP executes its growth plan, it could become the go-to non-Chinese supplier for any company needing rare earth materials or magnets. This first-mover advantage in restoring a Western magnet supply chain could yield network benefits (attracting key customers who want a reliable partner). Essentially, MP has a chance to capture market share early in a strategically important industry, which could cement its leadership and pricing power outside China.

- Solid Balance Sheet and Improving Financial Outlook: Unlike many upstart mining companies, MP Materials has had periods of strong profitability and maintains a solid financial position. In 2021-2022, when rare earth prices were high, MP was highly profitable – it earned $289 million net income in 2022 with nearly 55% net margins[9][8]. Those profits bolstered its balance sheet (over $1.2 billion cash at end of 2022)[48], giving it capital to invest in Stage II and III expansions. While 2023 saw a dip into losses due to lower prices and heavy investment, management has guided that the company will return to profitability by Q4 2025 as the price protection agreement and new production kick in[49]. The price floor from DoD virtually ensures positive cash flow from NdPr sales going forward, even if market prices are soft[44]. Meanwhile, the Magnetics division is already contributing positive EBITDA ($9.5M in Q3’25) during its ramp[50][10]. Bulls argue that the worst of the financial growing pains may be over. With major capex projects supported by government funds and loans (e.g. $1 billion financing committed for the new magnet plant[51]), MP’s execution risk on funding is reduced. As volumes increase and integration synergies kick in, the company could see margins expand again. In short, MP is not a cash-starved junior – it’s well-funded and on the cusp of a new earnings upcycle if all goes according to plan.

- National Security Narrative and ESG Appeal: As a kicker, MP Materials fits themes that many investors find attractive beyond pure numbers. It is a national security play – providing critical materials for defense and industrial independence, which can garner bipartisan political support. It’s also an ESG (environmental, social, governance) story in that rare earths are vital for enabling clean energy and decarbonization (EVs, wind turbines). Investors who want exposure to climate tech or to “strategic metals” for defense may find MP appealing. The company touts its environmentally conscious practices at Mountain Pass (recycling water, dry tailings, etc.)[52][53], trying to differentiate from China’s more polluting legacy operations. While softer factors, these narratives can broaden the shareholder base (e.g. institutions mandated to buy ESG-friendly or U.S.-security-related investments). The DoD investment in MP can be seen as a strong endorsement that could catalyze further institutional interest.

In summary, the bull case for MP envisions the company as a linchpin of the future economy’s supply chains – a high-growth, government-backed critical minerals company that will ride the EV and clean tech wave while enjoying protection from the usual pitfalls of commodities. With supportive tailwinds and its integration strategy, MP could evolve into a strategic, high-margin manufacturing business rather than just a mining company, which is exactly what excites long-term investors.

The Bear Case & Risks

Despite the promising story, investors must also consider the bear case and significant risks associated with MP Materials. Here are the primary concerns and challenges:

- Commodity Pricing Risk & Cyclicality: Rare earth prices are notoriously volatile and largely driven by Chinese supply dynamics. Boom-bust cycles have happened before – for example, neodymium-praseodymium (NdPr) oxide prices soared above $130/kg in 2022 only to crash to around $50–60/kg in 2023 as China increased supply and “guided” prices down[24][54]. MP’s fortunes have and will swing with these price changes; indeed, when prices fell in 2023, MP’s revenue dropped and it went from big profits to quarterly losses[12][9]. Although the new DoD price floor of $110/kg provides a buffer, it applies to a certain volume (stockpile or DoD purchases)[42] – it’s unclear if all production is covered or how it’s accounted under revenue (the company indicated the floor’s benefit will be recognized below revenue in accounting)[49]. There’s also a risk that rare earths remain a China-influenced commodity; if China floods the market with cheap supply to maintain dominance (a tactic used in the past), it could cap global prices and hurt MP’s non-floor-protected sales[55][56]. Additionally, rare earth demand, while growing, is subject to macroeconomic cycles – e.g. if EV sales slow in a recession, NdPr prices could dip. Bears argue that MP is still fundamentally a commodity play with all the associated volatility, and any sustained downturn in rare earth prices could pressure its finances (the DoD support is time-limited and specific). In short, price risk is the single biggest factor – rare earth markets are small and easily oversupplied, which could make MP’s revenue and stock price quite cyclical.

- Chinese Dominance & Geopolitical Wildcards: While MP is meant to solve reliance on China, it cannot escape China’s influence. China still controls ~90% of rare earth refining and magnet production[57][58]. Until MP fully completes its own processing capabilities, it remains partly tied to Chinese processing for certain outputs (historically MP sent its concentrate to China via an offtake partner). Even after domestic separation, China sets the reference price for rare earth oxides – most contracts globally (including MP’s past contracts) were indexed to Chinese prices[59]. This means Chinese policy decisions (export quotas, tariffs, or production quotas) directly affect MP’s economics. A bear case scenario is that China could respond to MP’s emergence by temporarily undercutting prices to make Western production uneconomic (a classic predatory pricing move). Beijing has done similar things in the past – in 2022 when prices were high, authorities ordered producers to bring prices “to rationality,” which promptly caused a steep decline[24]. If China’s strategy shifts, MP could face margin pressures or market share issues. On the other hand, an extreme geopolitical event (e.g. a conflict over Taiwan) could disrupt MP’s business in other ways – China might embargo exports of the processing reagents or equipment MP needs, or even the flow of heavy rare earth feedstock (since MP might have to import some heavies initially). Geopolitics is a double-edged sword: while tensions create opportunity (for MP’s strategic role), they also introduce unpredictability. For instance, if relations improve and China floods the market with supply, Western urgency to source from MP could wane, hurting the “strategic premium” for MP’s products. In sum, MP operates in the shadow of a powerful incumbent (China), and that shadow presents ongoing risks.

- Execution Risk – Stage II and III Ramps: MP Materials is undertaking an ambitious transformation that involves complex chemical processing and manufacturing steps that it has never done at full commercial scale. Refining rare earths (separating oxides) is a challenging process with tight tolerances and environmental hazards. Magnet production is even more specialized – it involves metallurgical expertise, sintering or bonding processes, and dealing with intellectual property (patents on magnet compositions are largely held by others, e.g. Hitachi). There’s significant technology and execution risk in MP successfully ramping its new facilities. For example, MP has been commissioning its Stage II separation plant; any startup issues, delays, or yield problems there could bottleneck the supply of NdPr for Stage III. Similarly, making high-performance NdFeB magnets consistently is not guaranteed – quality issues or slower-than-expected learning curves could occur. The company did reach an important milestone by late 2025 (initial magnet output), but producing at scale with high quality (targeting 1,000+ tonnes per year of magnets by around 2026) is the next challenge[16]. We should recall that MP’s predecessor, Molycorp, tried a technologically complex new separation process a decade ago and struggled, leading to bankruptcy. While MP’s team and tech might be better, the mineral processing field is full of delays and hiccups. Bears will point out that MP has already pushed some timelines – for instance, the Fort Worth magnet plant was initially expected to start ramping in 2023[60], but as of late 2025 finished magnets were only just beginning to be produced[61] (roughly a year behind the original schedule). Any further delays in hitting production milestones (like achieving commercial volumes of magnets by 2026, or the heavy RE separation coming online by mid-2026) could disappoint investors and derail financial projections. Execution risk also extends to cost overruns – building new refineries and factories can be expensive, and if costs exceed budget, MP might face financial strain or need to raise more capital.

- Heavy Rare Earth Dependency & Supply Challenges: A specific technical risk is that MP’s mine has very low concentrations of heavy rare earth elements like dysprosium (Dy) and terbium (Tb)[62]. These heavy REEs are crucial additives for magnets to function in high-temperature applications (EV motors, for example, need Dy/Tb for heat resistance). MP’s current ore is ~98% light rare earths; it contains less than 2% medium/heavies[62]. The company has stockpiled a few hundred tons of heavy-enriched concentrate, but that material itself only contains about 4% Dy/Tb[63] – in other words, MP does not own a significant primary source of heavies[62][64]. They plan to open a heavy rare earth separation facility in 2026 to process heavies, but the catch is they need to find feedstock for it. MP will likely have to import heavy rare earth concentrates from elsewhere (potentially from allies like Brazil, Africa, or recycling sources). Securing a stable and affordable supply of heavy REEs is a risk – these materials are extremely scarce outside China. For perspective, dysprosium prices ex-China are triple the Chinese domestic price ($900/kg vs $255/kg) due to scarcity[28]. If MP cannot line up enough heavies, it might limit its ability to produce the highest-grade magnets or meet certain customer specs. The Western world as a whole is scrambling here; forecasts suggest that by 2035, mines outside China will meet only ~29% of the heavy rare earth demand needed by auto and wind sectors[65]. MP is trying to mitigate this by deals (the Apple recycling partnership will provide some recycled Dy/Tb, and management said they’re engaging other feedstock suppliers[66]). But it’s a formidable challenge – bulls say MP is well positioned, bears worry that heavy RE bottlenecks could become a critical Achilles’ heel that either raises MP’s costs (buying heavies at high prices) or constrains its magnet output. In short, MP’s mine alone is not a full solution; it needs an ecosystem of heavy RE supply, which is still nascent.

- Dilution and Capital Needs: MP has big growth plans that require substantial capital. While it has cash and some government funding, the scale of investment is huge – for example, the newly announced “10X” magnet factory (to add ~7,500 tonnes more magnet capacity by 2028) will cost around $1 billion, which MP is financing through bank loans and presumably some equity components[51]. In fact, as part of the DoD deal, the U.S. government is purchasing $400 million of convertible preferred stock in MP plus warrants[67]. This will make DoD the largest shareholder but also means 15% dilution of existing shareholders (if converted) at a price of $30.03/share[33]. That’s a tangible dilution event. Future expansions could similarly involve issuing equity or equity-linked securities (though MP will try to leverage loans and grants first). Bears caution that share dilution is a risk, especially if project costs rise or rare earth prices slump (making external financing necessary). If MP’s stock price doesn’t perform, raising capital could become harder or more dilutive. Moreover, being partly government-funded can have drawbacks: the terms of the DoD deal, for instance, might prioritize strategic outcomes over immediate shareholder returns (e.g. the price floor helps the company but also effectively socializes some market risk to taxpayers). Some investors might worry that MP’s close government ties could limit certain commercial freedoms (though overall it’s more a positive). Still, from a pure financial perspective, current shareholders are sharing the pie with Uncle Sam and potentially future partners.

- Competition and Market Share Risk: While MP is ahead in the U.S., it’s not without competitors globally. Lynas Rare Earths, based in Australia, is the other major ex-China producer. Lynas has a large light rare earth output and has now started its own heavy rare earth separation (the first outside China) in Malaysia[68]. Lynas is also building a processing plant in the U.S. (with DoD funding) to supply separated light rare earths in Texas, expected in coming years. If Lynas successfully executes, it will remain a strong competitor, potentially with greater heavy RE access from its Mt. Weld ore and partnerships. There are also newcomers: in magnets, Vacuumschmelze (VAC), a German firm, just opened a magnet plant in the U.S. and is securing heavy RE supply deals[69][70]. Companies like NEO Performance Materials (Canada) or Shin-Etsu (Japan) are smaller players that could expand or partner with Western supply. And Chinese companies could circumvent export controls by building facilities in Southeast Asia or elsewhere, effectively extending their reach (some Chinese magnet makers have looked at Vietnam, for example). The risk is that MP might not corner the market as completely as bulls expect – customers will likely dual-source or multi-source for security, meaning MP may have to compete on price and service. If multiple rare earth projects (like those in Canada, Africa, etc.) come online by late decade, the supply landscape could be less constrained, which might pressure pricing or MP’s market share. Additionally, alternate technologies could nibble at rare earth demand: for example, some EV makers (Tesla, notably) are researching motors that use no rare earth magnets. If a viable non-REE motor technology gained traction industry-wide, it could cap the long-term demand growth for magnets (this is not imminent, but it’s a longer-term innovation risk to watch). Bears thus see MP as facing competitive and technological uncertainties – it’s not guaranteed that MP can maintain pricing power, especially post-2030 if the rest of the world ramps up projects (e.g. projects in Greenland, Brazil, etc., or recycling efforts at scale).

- Operational and Environmental Risks: As a mining and chemical processing company, MP also carries typical operational risks. Mining operations could be disrupted by accidents, equipment failures, or regulatory issues. Mountain Pass had historical environmental controversies (radioactive wastewater in the past); while MP operates more cleanly (closed-loop system)[71], any environmental incident could halt production or incur costs. California is a state with strict regulations – MP must maintain compliance to avoid any shutdowns. There’s also the risk of resource depletion or grade decline: the mine’s known reserves are substantial, but if actual ore grade or recovery rates differ, it could affect output. Processing rare earths produces chemical waste – if regulations tighten further or waste handling hits a snag, that could slow MP’s ramp. Moreover, things like earthquakes or other natural issues (Mountain Pass is in a seismically active region) could pose physical risk. While these might be low-probability, they’re not zero. Finally, MP has a significant relationship with one customer historically (a Chinese partner that took its concentrate). As it transitions, it will need to manage new customer relationships and credit risks – e.g. if a major customer like GM had an EV slowdown, it could ripple to MP’s orders. All told, MP faces a complex risk landscape beyond just mining – spanning manufacturing, international trade, and policy.

In summary, the bear case views MP Materials as a company with a great story but one that must overcome serious challenges: reliance on a volatile commodity market (historically dominated by China’s whims), the steep learning curve of new production processes, supply constraints in critical inputs (heavy rare earths), and the need to spend heavily (with possible dilution) amid emerging competition. Skeptics might say MP is not the first U.S. rare earth venture to be hyped – but previous iterations ended poorly when the market turned. They caution that while MP is better positioned now, it is not immune to the economic and geopolitical realities that make this industry tricky. Investors, therefore, should weigh these risks and not get swept up in the strategic narrative alone.

Financial & Strategic Snapshot

To evaluate MP Materials, it’s helpful to look at its recent financial performance and major strategic initiatives at a high level. This provides context on how the company is evolving from a financial standpoint:

Revenue and Profit Trends: MP’s financials have been on a roller coaster due to rare earth price swings and its reinvestment phase. In 2021 and 2022, the company benefited from high rare earth prices and achieved excellent results – for full-year 2022, MP reported $527.5 million in revenue (up 59% YoY) and $289 million in net income[9][8]. Those were record profits, reflecting strong NdPr pricing and high production volumes (2022 saw the highest annual REO output in U.S. history from Mountain Pass)[9]. MP’s EBITDA margins were very robust (>70% adjusted EBITDA margin in 2022)[9][8], showing the cash-generating potential when market conditions are favorable. However, 2023 brought a reversal. Rare earth prices fell significantly, and MP simultaneously started reducing external sales to build its own processing inventory. As a result, revenues dropped and the company posted net losses in multiple quarters of 2023 and 2024. For example, in Q3 2025 MP had revenue of $53.6M (down 15% YoY) and a net loss of $41.8M[11][12]. This dip was anticipated as part of the “Stage II/III” transition – MP was effectively sacrificing short-term sales (no longer selling all its concentrate) to channel material into its new separation plant. The good news is that MP expects this transition period to bottom out by the end of 2025: management has guided a return to profitability in Q4 2025, aided by the new price floor income and initial magnet sales[49].

Segment Breakdown: The company now reports two segments – Materials (legacy mining & oxide sales) and Magnetics (the downstream manufacturing). The Materials segment has seen a revenue decline as MP stopped selling raw REO externally; in Q3 2025 Materials revenue was ~$31.6M, down from $55M+ two quarters prior[72]. That segment even showed a negative EBITDA in mid-2025 because the operation was running but stockpiling product (no revenue) and bearing higher unit costs during ramp-up[12]. Meanwhile, the Magnetics segment has grown from scratch to $21.9M revenue in Q3 2025 with $9.5M adjusted EBITDA[73][10]. This Magnetics revenue so far likely comes from selling NdPr metal/alloy (and maybe some pilot magnet output) – interestingly some of it might be intercompany sales that will feed into final magnets[74]. The key point is that by 2025, MP has started to diversify its revenue mix: about 40% of Q3 2025 revenue was from the Magnetics segment[72], whereas a year or two ago it was 0%. Over the next few years, we should see Materials (sale of separated oxides to external customers or internal use) and Magnetics (sale of alloy, magnets to customers like GM) both scale up. Investors should expect a higher-value revenue mix going forward, but also possibly higher operating costs as manufacturing is more expensive than just mining.

Major Projects (“Stages”): Strategically, MP is executing a phased growth plan. Often discussed in three stages: Stage I was restoring the mine and producing concentrate (achieved, Mountain Pass reopened in 2017 and ramped by early 2020s). Stage II is refining/separation – MP has invested in facilities at Mountain Pass to produce separated rare earth oxides, notably NdPr oxide, instead of selling carbonate concentrate. By late 2023, MP was commissioning these assets and producing initial volumes of NdPr oxide (they hit record NdPr oxide production of 721 tonnes in Q3 2025)[73]. Stage II is reaching completion, enabling MP to supply its own Stage III and external oxide customers. Stage III is magnet production – the Fort Worth, Texas NdFeB magnet factory (sometimes called the “Stage III facility” or by its nickname “Project Independence”). Construction began in 2022, and MP started producing magnet precursors (alloy flakes) in 2024 in pilot mode[75]. The company expected to ship first finished magnets by end of 2025[61], and scale up in 2026. This facility is sized for ~1,000 tonnes/year magnets initially[16]. Beyond Stage III, MP announced in 2025 a further expansion: a second, larger magnet factory (dubbed the “10X Facility”) to open around 2028, with 10,000 tonnes/year capacity[76]. That is funded by the DoD partnership and will effectively make MP one of the world’s largest magnet producers outside China, if it materializes. Additionally, MP is adding a heavy rare earth separation unit at Mountain Pass by 2026 (supported by a $150M DoD loan)[51]. This will allow them to process Dy/Tb (sourced externally) and incorporate heavies into magnets domestically.

Profitability Path: The near-term profitability will depend on a few factors: the NdPr price (now bolstered by the floor from Q4 2025 onward), the ramp-up efficiency of the separation plant (which should lower unit costs by producing higher-value oxide instead of selling cheap concentrate), and the expenses of running new operations. MP’s management has indicated that as of Q4 2025, with the price floor in effect and more oxide output, the Materials segment should flip back to positive margin[77]. Magnetics is already EBITDA-positive in pilot phase, which is a good sign. However, as they fully start magnet production, depreciation and overhead will increase, likely pressuring margins until volume picks up in 2026–2027. Analysts expect MP’s earnings inflection to happen in 2024–2025 as these pieces come together[49]. By 2026, if all goes well, MP could be firing on all cylinders – selling separated NdPr oxide (some to external customers at hopefully improved prices) and selling magnets to customers like GM (which is slated to begin magnet-related revenue in H2 2026 according to guidance)[78]. The DoD price floor ensures that MP gets at least $110/kg for NdPr either via stockpile sales or presumably through a compensation mechanism[42]. For context, $110/kg is a very healthy price – Lynas, the Australian peer, was realizing the equivalent of ~$40/kg for its mixed REO in mid-2025 due to Chinese price depression[79]. So MP essentially has a floor at nearly 3x what competitors were getting at the trough, which bodes well for its cash flow stability. Longer term, if magnet operations ramp to significant scale, MP’s revenue mix will include more engineered products, which could make earnings less directly tied to daily commodity prices (instead more tied to contract pricing).

Balance Sheet and Funding: MP had about $1.2 billion in cash at 2022’s end[48], and even after capex spend, it had a substantial cash reserve through 2023 (exact current cash not given here, but presumably still a few hundred million at least, plus untapped credit lines). The company issued $690M of Green Convertible Bonds in 2021 (due 2026), giving it low-interest debt financing for expansion. The DoD deal in 2025 adds $550M of new funding ($400M preferred equity, $150M loan) and opens access to $1.0B in commercial loans for the 10X plant[51][67]. MP’s capital expenditures have been high (building separation circuits, the Texas factory), but with these financing sources, it appears to have the funds to complete current projects without needing to tap equity markets imminently. Its net debt is still modest (it was in a net cash position through 2022; now with convertibles and some loans, debt will increase but should be manageable). Essentially, MP has proactively funded its growth with a combination of equity (from the SPAC and follow-ons), bonds, and now government support. Investors will want to watch that MP doesn’t overleverage or overspend, but for now the strategic financing means financial risk is somewhat mitigated.

Major Partnerships and Contracts: On the strategic front, MP’s commercial agreements are noteworthy. The GM magnet supply agreement (announced 2021) is a cornerstone, indicating at least 12 models’ worth of demand once MP’s magnets are ready[13]. This gives a built-in revenue stream (though the exact volume/offtake schedule isn’t public). The Apple agreement in 2023-2024, which involved Apple prepaying $100M+ for materials to secure recycled rare earth content[17], signals another major end-customer alignment – Apple’s interest suggests MP’s materials might eventually go into Apple products (Apple has stated a goal to use 100% recycled rare earths in its devices; MP could be helping with that via recycling programs). Then there’s obviously the U.S. government – not just as an investor, but as a customer (the military will likely buy magnets or material from MP for weapon systems). Collectively, these partnerships validate MP’s strategic importance and also reduce market risk (MP is not solely relying on spot market sales; it has long-term buyers in place). Strategically, MP is also aligning with allied supply chains – e.g., it signed a distribution deal with Sumitomo Corporation in Japan to serve Japanese rare earth customers[80]. This could help it tap markets like Japanese automakers or electronics firms with its separated products.

Competitive Position: Financially, MP’s low production cost at Mountain Pass (due to scale and it being a bastnaesite ore which is relatively high-grade for light REEs) has historically been an advantage. During high price periods, MP enjoyed fat margins – its cost to produce a ton of REO concentrate was much lower than the selling price at 2021-22 peaks, hence the huge profits. When prices fell, MP roughly broke even at the mine on an EBITDA basis, which implies its production cost for NdPr in concentrate was near the prevailing price (~$60/kg). With the floor now at $110, Mountain Pass operations should be comfortably profitable again. Compared to Lynas, MP’s cost structure might be similar or a bit higher in some aspects (Lynas benefits from high NdPr grades at Mt Weld, but has extra costs shipping to Malaysia). A strategic snapshot would note that MP and Lynas are the two dominant Western rare earth producers, with MP now attempting to outflank Lynas by going into magnets. Lynas’s FY2023 revenue was about A$741M (roughly US$500M) at lower prices, comparable to MP’s $527M in 2022 at higher prices – so they’re of similar scale in mining. Financially, Lynas has been profitable but also saw profit drop in 2023 due to prices. The takeaway: MP is among the leaders in this niche and is now differentiating itself by vertical integration.

Overall, the financial and strategic snapshot of MP Materials shows a company in transition. It had a period of strong cash generation, used that to invest in growth, weathered a cyclical downturn, and is now on the brink of producing higher-value products with crucial backing. Investors should keep in mind that near-term financials (past year or so) reflect heavy investment and temporarily lower sales, but the forward-looking picture includes new revenue streams (magnets, separated oxides), improved price stability (thanks to government support), and the potential for significant growth as the new facilities come online. Major projects like the heavy RE separation and the 10X magnet plant are in the pipeline, which means capex will continue but also that MP’s scope of business will broaden. In a sense, MP 2026+ will look very different from MP 2020 – more like an advanced materials company with multiple product lines, rather than a single-mine concentrator. This evolution will be critical to monitor in the financials, as investors will want to see margin improvement and revenue diversification as proof that the strategy is paying off.

What Investors Should Watch

For those interested in MP Materials as an investment, there are several key factors and catalysts to keep an eye on going forward. These will likely determine how the stock performs and whether the company’s strategy stays on track:

1. Rare Earth Prices (NdPr in particular): Given the importance of neodymium-praseodymium pricing to MP’s revenue, investors should monitor price trends for NdPr oxide. Any significant moves – up or down – will impact MP’s earnings. For instance, if NdPr prices rebound strongly above the $100/kg level (perhaps due to demand surges or Chinese supply cuts), MP’s topline could get a nice boost (on top of the DoD floor). Conversely, if prices languish around ~$60 or if China tries to push them even lower, it could weigh on sentiment (though MP now has the price floor safety net for a portion of its sales[44]). Remember that the DoD price floor of $110/kg effectively started in Q4 2025[49], so one thing to watch is how MP accounts for and utilizes this floor. The Q4 2025 and Q1 2026 earnings reports will likely show how much benefit the price floor provides – e.g., does MP sell NdPr at market price and then record an additional “income” to bring it up to $110? Understanding that will help in modeling cash flows. In summary, keep an eye on rare earth price indices (Asian Metal or others) and any news of Chinese production or export policy changes, as these drive the price of MP’s underlying commodity.

2. Magnet Production Ramp and Customer Uptake: 2024 through 2026 are critical years for MP’s downstream business. Investors should watch for updates on the Fort Worth magnet factory’s output. Key questions: Is MP hitting its milestones (producing commercial-quality magnets, meeting volume targets)? Is it on schedule to deliver magnets to GM and other customers? By late 2025, MP aimed for first commercial magnet output[81], and magnet revenue is expected to start contributing meaningfully in H2 2026[78]. Each quarterly earnings or investor call will likely discuss magnet segment progress – listen for metrics like how many tonnes of alloy or magnets produced, yield rates, etc. Additionally, keep an ear out for new customer deals or expansions. For instance, MP has one known major magnet customer (GM) and another in Apple (for materials), but will they announce supply agreements with other automakers, wind turbine manufacturers, or defense contractors? Landing another big magnet offtake deal could be a catalyst for the stock by validating demand. Conversely, if there are delays or quality issues (e.g., if GM’s timeline for sourcing from MP slips), that would be a warning sign. Basically, execution in magnet manufacturing is something the market will scrutinize closely, as it’s new territory for MP.

3. Commissioning of Heavy Rare Earth Separation: By mid-2026, MP plans to bring its heavy rare earth separation online (for Dy/Tb)[82]. Investors should watch whether this comes on time and how MP sources the feedstock. Announcements of supply agreements for heavy rare earth concentrate (from mines or recyclers) would be positive, as it means MP can utilize that new plant. This might include partnerships with companies like those developing heavy-rich projects (e.g., a deal with a Brazilian or Canadian project could happen). If mid-2026 comes and we hear that heavy RE separation is operational and perhaps already supplying material for magnet production, that’s a big de-risking event – it would show MP can produce the full range of magnet inputs domestically. If, however, this project is delayed or underutilized (due to lack of feed or technical issues), that could limit MP’s magnet capabilities (magnets for EVs really need Dy). So keep an eye on any news regarding dysprosium/terbium production at Mountain Pass and related supply deals.

4. Policy and Regulatory Developments: The rare earth sector is heavily influenced by government policy globally. A few things to watch on this front:

- In the U.S., any new legislation or executive actions that affect rare earth mining or manufacturing. For example, if the U.S. imposes requirements for defense contractors to buy American rare earth products, that directly benefits MP. Or if additional funding programs (like Defense Production Act initiatives or Dept. of Energy grants) are announced for rare earth projects, MP might get further support. On the flip side, any changes to environmental regulations or permitting that make operations harder could be a risk (though MP already runs in California’s strict regime, so likely fine).

- In China, export policies are key. China’s export controls on magnet alloy (imposed in 2023-2025) were a catalyst that drove Western buyers to MP[25][83]. If China were to remove or loosen those export restrictions, some pressure might come off Western supply chains (possibly easing urgency). Conversely, if China tightens the screws further – say outright banning exports of certain rare earth oxides or magnets – that could cause panic buying from MP or others and potentially spike prices (helping MP financially, but also possibly prompting more government intervention). Investors should monitor U.S.-China trade negotiations and any mention of rare earths (for instance, the temporary deal in late 2025 where China agreed to delay new controls – such developments can impact sentiment).

- Also internationally, allied countries’ actions: Europe has been talking about critical minerals strategy; if, say, the EU started subsidizing rare earth magnet factories or stockpiling, that could benefit MP if it can export there. Or if allied nations create a coordinated stockpile (there’s been talk of U.S.-Japan-EU cooperation), MP might have opportunities to sell into those programs.

In short, the policy environment is dynamic – almost any significant policy move regarding rare earths will have an effect on MP, so staying informed via news from DoD, DOE, and foreign ministries is worthwhile.

5. Earnings Reports & Cost Trajectory: On a micro level, continue to analyze MP’s quarterly earnings for several things: cash burn vs. cash on hand, updates to capex guidance, and cost of production metrics. For instance, if MP starts generating cash again in late 2025 as expected, that reduces risk of needing new financing. If, however, capex overruns are disclosed or opex is higher than expected (perhaps the new facilities are expensive to run initially), those would be caution flags. Watch MP’s unit cost of production once they start reporting separated oxide costs – are they managing to produce NdPr oxide at a competitive cost? (We may glean this indirectly from margins.) Also, watch inventory levels – during the transition MP built inventory; we’ll want to see that convert to sales as the separation plant and magnet plant ramp. Any guidance on 2026 volumes (for both oxide and magnets) will be important for forecasting the growth curve. Essentially, each earnings call is a check-in on the execution timeline and financial health.

6. Competitive Developments: Keep tabs on what MP’s competitors and peers are doing, as this shapes the market context. Notably:

- Lynas: The Australian miner’s progress on its U.S. facility in Texas (which is supposed to produce separated light rare earths with DoD funding) and on expanding heavy RE output in Malaysia/Australia[84]. If Lynas faces delays (as it did with a temporary Malaysian shutdown in 2023 due to regulatory issues), MP might enjoy a more open field. If Lynas accelerates, then the non-China supply increase could put both in competition for customers. Lynas’s quarterly reports, which mention realized prices and production volumes, also act as a benchmark for the industry.

- New Projects: There are numerous junior rare earth miners globally. Most won’t impact MP in the immediate term, but by late 2020s some could come online (e.g., projects in Canada, Brazil, Africa). For instance, the Reuters piece noted deals by VAC with projects like Torngat (Canada) and Aclara (Brazil) for heavy rare earth supply[70]. If those projects succeed, they might supply others or even MP (collaboration or competition). Keep an eye on any mergers & acquisitions too – it’s conceivable MP could consider acquiring a heavy rare earth source or a smaller tech company to bolster its capabilities.

- Magnet Industry Moves: Are other companies building magnet capacity outside China? As noted, VAC opened a plant in the U.S., and there are talks of Japanese and European firms expanding. If a big player announces a magnet factory in North America, that could either be competition or possibly a customer for MP’s alloy. Also watch the patent landscape – as old patents expire (Hitachi’s core NdFeB patents largely expired by 2022), more entrants can make magnets, which could increase competition but also free MP from paying license fees.

- Technological shifts: Unlikely in the near term, but keep an eye on whether automakers seriously move to magnet-free motors or reduced rare earth content (Tesla’s announcement of a next-gen motor with no rare earths caused a stir in early 2023). If such innovations start materializing at scale, it could moderate rare earth magnet demand in the auto sector. Currently, most experts think NdFeB will remain dominant for performance reasons[85], but it’s a space to watch given rapid R&D in EV technology.

7. Catalysts & Newsflow: Besides the above, specific catalysts that could move MP’s stock in the medium term include:

- Successful commissioning announcements (e.g. “MP produces first magnets” – which likely happened in late 2025, any official confirmation would be a milestone).

- Signing of the definitive GM supply contract terms (the 2021 announcement was binding, but full supply agreement details might be updated as production starts).

- Expansion of existing contracts: If GM or another major customer extends contracts or increases orders, that would be a bullish signal. For example, GM currently plans for magnets for 12 models; if they expand that to all their EVs or add more years, it shows confidence in MP.

- Inclusion in stock indices or receiving government designation (MP is already somewhat high-profile, but if any broader index or ETF picks it up more heavily due to ESG or critical mineral themes, that could affect demand for the stock).

- Changes in Chinese policy: e.g. if China were to put tariffs on rare earth exports or enforce an outright ban on exporting refined oxides, MP’s strategic value would skyrocket practically overnight – though we hope it doesn’t come to an extreme trade war scenario, it’s something to stay aware of.

- Any unexpected hiccups: On the flip side, if MP had a setback such as a production shortfall, a major cost overrun, or an accident at the mine or plant, that would likely be disclosed and would be important to re-evaluate assumptions.

In summary, investors in MP Materials should adopt a multi-faceted watchlist: monitor commodity pricing trends and Chinese policy (for the macro backdrop), track MP’s project execution and output volumes (for operational success), and follow partnerships and policy support (for demand security). It’s a story where both global events (trade tensions, climate policy) and company-specific execution will drive outcomes. Staying updated through company press releases, earnings calls, and industry news will help investors gauge whether MP is delivering on its promise of becoming a rare earth powerhouse, or if it’s hitting bumps along the way.

Conclusion

MP Materials presents a fascinating investment narrative at the intersection of commodities, technology, and geopolitics. So, is MP a speculative bet, a strategic long-term hold, or a cyclical commodity play? In truth, it has elements of all three.

On one hand, MP is undoubtedly a strategic, long-term story. The company is integral to Western efforts to secure critical minerals supply chains, and it has garnered unparalleled support (and oversight) from the U.S. government. If you believe in the megatrends of EVs, clean energy, and the re-shoring of advanced manufacturing, MP Materials can be seen as a long-term holding that stands to benefit from these secular shifts. Its plans to become a fully integrated rare earth magnet producer suggest it could evolve into a kind of “strategic utility” for the tech and defense industries – a go-to domestic supplier that enjoys steady demand. From this perspective, one might view MP as a strategic asset to hold onto as the world electrifies and decarbonizes, expecting its importance (and potentially its pricing power) to grow over time.

On the other hand, rare earths remain a cyclical commodity market to a significant degree. MP’s financial results have mirrored the rise and fall of NdPr prices. The stock is likely to experience volatility based on macro forces like Chinese export moves, global manufacturing cycles, and investor sentiment toward commodities. In that sense, MP could trade like a cyclical mining stock, with booms when shortages occur and pullbacks when there’s oversupply. Investors need to be prepared for the inherent ups and downs – rare earth prices have historically been anything but stable. Until MP’s magnet business matures to where contract sales can smooth out the bumps, the company will still feel like a commodity player at times.

There’s also a case to be made that MP is a speculative investment at its current stage. It carries execution risks and is pricing in a lot of future success. The company’s valuation (market cap) reflects optimism about hitting milestones that are still in progress. An investor today has to have confidence not only in rare earth demand, but also in MP’s ability to deliver on building high-tech processing facilities and winning in the market against established global competitors. That requires a degree of faith – the pieces are falling into place, but aren’t all proven yet. Thus, MP is speculative in the sense that it’s not a mature, cash-cow company; it’s an evolving venture that is betting on a certain vision of the future.

Weighing these aspects, MP Materials looks like a hybrid: it is a strategic long-term play with a speculative edge, operating in a cyclical industry. For a retail investor, the appeal is clear – MP gives direct exposure to themes like EVs and national security that few other stocks do. But it should be approached with realistic expectations and an understanding of the risks. The company could very well become the linchpin of a non-China rare earth supply chain, earning consistent revenues from magnets and enjoying policy tailwinds (that’s the bull case we outlined). If that happens, MP could be a multi-decade winner as the world’s economies electrify. However, if execution falters or if the rare earth market is undermined by external forces, MP’s stock could feel the sting, at least in the medium term.

Investors should evaluate MP Materials based on their own risk tolerance and time horizon. For long-term believers in the critical minerals thesis, MP might be seen as a core holding – one that you monitor over years as it potentially scales into a vertically integrated powerhouse. For more tactically-minded investors, MP could be a cyclical trade – buy when rare earth prices are depressed and policy support is rising, and trim when euphoria and prices are high. And for everyone, keeping an eye on the execution milestones in the next 1-2 years is crucial; those will likely determine if MP graduates from a promising project to a profitable, enduring business.

In conclusion, MP Materials sits at a unique crossroads of opportunity and risk. It’s speculative in the short term as it builds out its capabilities, strategic in the long term given its role in enabling the future of technology and defense, and cyclical by the nature of the market it operates in. As with many investments, the reality will probably land somewhere in the middle of the extreme outcomes. MP has a chance to justify the hype by becoming an anchor of Western rare earth supply – but investors should proceed with both optimism for its vision and caution for the hurdles ahead. This balanced approach will allow one to appreciate why MP Materials matters, while also remembering that in the world of rare earths, nothing comes easy.

[1] [13] [14] [15] [16] [20] [34] [36] [46] [47] [52] [53] [60] [71] MP Materials – MP Materials to Build U.S. Magnet Factory, Enters Long-Term Supply Agreement with General Motors

[2] [26] [29] [30] [32] US could limit dependence on China for rare earths within three years: MP Materials | S&P Global

[3] [23] [35] [37] [57] [58] [85] What is Rare Earth Elements: Magnets, EV Motors, Supply Chain & Prices | Benchmark Minerals

[4] [5] [31] [33] [39] [40] [42] [43] [51] [67] [76] MP Materials Announces Transformational Public-Private Partnership with the Department of Defense to Accelerate U.S. Rare Earth Magnet Independence | MP Materials

[6] [18] [19] MP Materials to Build U.S. Magnet Factory, Enters Long-Term Supply Agreement with General Motors

[7] [21] [22] [41] [61] [75] MP Materials – MP Materials Awarded $58.5 Million to Advance U.S. Rare Earth Magnet Manufacturing

[8] [9] [48] [80] MP Materials – MP Materials Reports Fourth Quarter and Full Year 2022 Results

[10] [11] [12] [49] [50] [72] [73] [74] [77] [78] [81] [82] MP Materials Corp. / DE (MP) Q3 2025 Earnings Summary | Fintool

[17] [27] [28] [45] [62] [63] [64] [65] [66] [68] [69] [70] [84] West scrambles to fill heavy rare earth gap as China rivalry deepens | Reuters

[24] [25] [38] [44] [54] [55] [56] [59] [79] [83] Emergence of an Ex-China Rare Earth Pricing Index

Emergence of an Ex-China Rare Earth Pricing Index